- +86 18120750932

- colin@xmsinuowei.com

- th.xmsinuowei.com

The pioneering years in the history of capacitors was a time when capacitors were used primarily for gaining an early understanding of electricity, predating the discovery even of the electron. It was also a time for doing parlor demonstrations, such as having a line of people holding hands and discharging a capacitor through them. The modern era of capacitors begins in the late 1800s with the dawning of the age of the practical application of electricity, requiring reliable capacitors with specific properties.

Marconi with transmitting apparatus, Published on LIFE [Public domain], via Wikimedia Commons

One such practical use was in Marconi’s wireless spark-gap transmitters starting just before 1900 and into the first and second decade. The transmitters built up a high voltage for discharging across a spark gap and so used porcelain capacitors to withstand that voltage. High frequency was also required. These were basically Leyden jars and to get the required capacitances took a lot of space.

In 1909, William Dubilier invented smaller mica capacitors which were then used on the receiving side for the resonant circuits in wireless hardware.

Early mica capacitors were basically layers of mica and copper foils clamped together as what were called “clamped mica capacitors”. These capacitors weren’t very reliable though. Being just mica sheets pressed against metal foils, there were air gaps between the mica and foils. Those gap allowed for oxidation and corrosion, and meant that the distance between plates was subject to change, altering the capacitance.

In the 1920s silver mica capacitors were developed, ones where the mica is coated on both sides with the metal, eliminating the air gaps. With a thin metal coating instead of thicker foils, the capacitors could also be made smaller. These were very reliable. Of course we didn’t stop there. The modern era of capacitors has been marked by one breakthrough after another for a fascinating story. Let’s take a look.

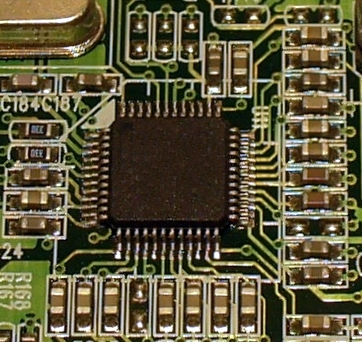

MLCCs around a microprocessor. By Elcap [CC BY-SA 3.0], via Wikimedia Commons

In the 1920s mica wasn’t as abundant in Germany and so they experimented with new families of ceramic capacitors, finding that titanium dioxide (rutile) had a linear temperature dependence of capacitance for temperature compensation and could replace mica capacitors. They were produced in small quantities at first and larger quantities in the 1940s. They consisted of a disc metalized on both sides.

To get higher capacitance another ceramic, barium titanate was used, as it had 10 times the permittivity of mica or titanium dioxide. However, they had less stable electrical parameters and could replace mica only where stability was less important. This was improved after World War II.

An American company launched in 1961 pioneered the multi-layer ceramic capacitor (MLCC) which was more compact and had higher capacitance. As of 2012 more than 10^12 barium-titanate MLCCs are produced each year.

Electrolytic capacitor

In the 1890s Charles Pollak found that an oxide layer on an aluminum anode was stable in a neutral or alkaline solution and was granted a patent in 1897 for a borax electrolyte aluminum capacitor. The first “wet” electrolytic capacitors appeared in radios briefly in the 1920s but had a limited lifespan. They were called “wet” due to their high water content. They were basically a container with a metal anode immersed in a solution of borax or other electrolyte dissolved in water. The outside of the container acted as the other plate. These were used in large telephone exchanges to reduce relay noise.

The patent for the electrolytic capacitor’s modern ancestor was filed in 1925 by Samual Ruben. He sandwiched a gel-like electrolyte between the oxide coated anode and the second plate, a metal foil, eliminating the need for a water filled container. The result was the “dry” electrolytic capacitor. Another addition was a paper space between the turns of the foils. All of this reduced the size and price significantly.

In 1936 the Cornell-Dubilier company introduced their aluminum electrolytic capacitors, including improvements such as roughening the anode surface to increase capacitance. The Hydra-Werke, an AEG company, began mass production in Berlin, Germany at the same time.

After World War II, the rapid development of radio and television technology lead to larger production quantities as well as a variety of styles and sizes. Improvements included reducing leakage currents and equivalent series resistance (ESR), wider temperature ranges and longer lifespans by using new electrolytes based on organics. Further developments from the 1970s to the 1990s also included lowering leakage currents, further reduction in ESR and higher temperatures.

What became known as the “capacitor plague” occurred during the years 2000 to 2005, possibly due to the use of a stolen recipe but without certain stabilizing substances leading to premature failure.

A surface-mount tantalum capacitor. By Epop [Public domain], via Wikimedia Commons

Tantalum electrolytic capacitors were first manufactured for military purposed in the 1930s. These used wound tantalum foils and a non-solid electrolyte. In the 1950s Bell Laboratories made the first solid electrolyte tantalum capacitors. They ground the tantalum to a powder and sintered it as a cylinder. At first a liquid electrolyte was used but they then discovered that manganese dioxide could be used as a solid electrolyte.

Although Bell Labs made the fundamental inventions, in 1954 the Sprague Electric Company made improvements in the process, producing the first commercially viable tantalum solid electrolyte capacitors.

1975 saw the emergence of polymer tantalum electrolytic capacitors with much higher conductivity conductive polymers replacing the manganese dioxide leading to lower ESR. NEC released their polymer tantalum capacitors in 1995 for SMDs (surface-mount devices) with Sanyo following suit in 1997.

Tantalum ore is subject to price shocks and two such occurrences happened in 1980 and 2000/2001. The latter shock led to the development of niobium electrolytic capacitors with manganese dioxide electrolyte delivering properties roughly the same as tantalum capacitors.

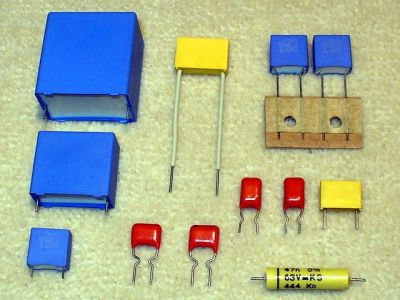

Film capacitors. Elcap [CC-BY-SA 3.0], via Wikimedia Commons

The metalized paper capacitor was patented in 1900 by G.F. Mansbridge. The metalizing was done by coating the paper with a binder filled with metal particles. These were commonly used in the early 1900s as decoupling capacitors in telephony (telecommunications.) During World War II, Bosch improved the process and manufactured them by coating the paper with lacquer and using vacuum deposition of metal to coat it. Around 1954 Bell Labs made a 2.5um-thick metalized lacquer film separate from the paper resulting in much smaller capacitors. This can be considered the first polymer film capacitor.

Research in plastic by organic chemists during World War II resulted in this going further. In 1954 the first

mylar capacitor was one of those. Mylar was trademarked by Dupont in 1952 and is a very strong PET (polyethylene terephthalate). In 1954 a 12um-metalized mylar film capacitor was produced. By 1959 the list included capacitors made with polyethylene, polystyrene, polytetrafluoroethylene, PET and polycarbonate. By 1970, electric utilities were using film-foil capacitors without the paper.

Supercapacitors, Maxwell Technologies, Inc. [CC BY-SA 3.0], via Wikimedia Commons

That takes us to the last of our capacitor types, and fairly exciting ones at that with capacitances in the thousands of farads. In the early 1950s researches at General Electric used their background with fuel cells and rechargeable batteries to experiment with capacitors with porous carbon electrodes. This lead to H. Becker patenting the capacitor as a “Low voltage electrolytic capacitor with porous carbon electrodes”, not understanding the principle behind it that lead to the extremely high capacity. GE didn’t pursue it further.

Standard Oil of Ohio developed another version and eventually licensed it in the 1970s to NEC who finally commercialized it under the trademarked name, supercapacitor. It was rated at 5.5V and had capacitances up to 1F. They were up to 5 cm^3 in size and were used as backup power for computer memory.

Brian Evans Conway ศาสตราจารย์กิตติคุณแห่งมหาวิทยาลัยออตตาวา ทำงานเกี่ยวกับตัวเก็บประจุไฟฟ้าเคมีไฟฟ้าชนิดรูทีเนียมออกไซด์ตั้งแต่ปี 2518 ถึง 2523 ในปี 2534 เขาได้อธิบายความแตกต่างระหว่างตัวเก็บประจุยิ่งยวดและแบตเตอรี่ในที่เก็บประจุไฟฟ้าเคมี โดยให้คำอธิบายทั้งหมดในปี 2542 ขณะที่บัญญัติคำว่าซุปเปอร์คาปาซิเตอร์อีกครั้ง

ผลิตภัณฑ์และตลาดเติบโตอย่างช้าๆ ด้วยชื่อผลิตภัณฑ์เช่น Goldcaps, Dynacap และ PRI Ultracapacitor ซึ่งเป็นซุปเปอร์คาปาซิเตอร์ตัวแรกที่มีความต้านทานภายในต่ำที่พัฒนาในปี 1982 โดย Pinnacle Research Institute (PRI) เพื่อวัตถุประสงค์ทางการทหาร

การพัฒนาที่ค่อนข้างเร็วในตลาด ได้แก่ ตัวเก็บประจุลิเธียมไอออนซึ่งเติมขั้วบวกของถ่านกัมมันต์ด้วยลิเธียมไอออน สิ่งเหล่านี้มีความจุเป็นพันฟารัด (4 หลัก) ที่ประมาณ 2.7V

จากความคิดเห็นของคุณในการตอบสนองต่อประวัติของตัวเก็บประจุ - โพสต์ปีแห่งการบุกเบิก ไม่มีปัญหาเรื่องการใช้คำว่าคอนเดนเซอร์แทนที่จะเป็นตัวเก็บประจุ ดังนั้นคำว่าตัวเก็บประจุมาจากไหน? ดูเหมือนว่าจะไม่เป็นที่รู้จัก แต่พจนานุกรมภาษาอังกฤษของอ็อกซ์ฟอร์ดอ้างอิงจาก 1922 BSI (British Standards Institution?) คำศัพท์ทางวิศวกรรมไฟฟ้าที่ระบุว่า 'ตัวเก็บประจุ' เป็น 'คำศัพท์ใหม่' และแนะนำให้ใช้เพื่อหลีกเลี่ยงความสับสนกับไอน้ำ 'คอนเดนเซอร์'.

ที่มา: HACKADAY

บริการออนไลน์